2022 DYNO PRICE SHEET-05/04/22 (INERTIADYNO.COM)

ALL PRICES SUBJECT CHANGE.

We now have dynos in 9 countries and over 300+ in North America, we’ve built a dyno for about anything that races. I built my first dyno in the winter of 1994/1995. It’s always best if we talk by phone (641-775-3395) so you can tell me about what you’re working on and future plans, so we can get you the right dyno for your application. I suggest you print this out, grab a highlighter and mark items you have questions about. Also, a legal pad and pen to write down other questions you have, like custom options. These always take more time, so they cost a little more.

See a dyno listed below you’re interested in, e-mail me with your information or country and I’ll give you an exact quote including freight. We can always add or take away any items on my quotes. I of course need your zip code. Freight & steel are both going up quickly right now, so don’t wait too long. All dynos include up to 1 hour training by phone. And of course, I’ll answer your follow up questions. Graphs, you send to me by smart phone if testing engines or clutches, so I’ll tell you what I see. All my dynos are able to dyno test clutches. If you’ve been in business over a year, we can probably get you leasing. Buy the dyno you really need and pay for it over time. You pay for 2-3 payments up front and then a monthly amount till it’s yours. Buy out at the end is $1.00. Leasing payments are fully deductible, talk to your tax person.

Water brake & hydraulic dynos- Yes, we still make them for engines using a governor. Engine rpm is limited to 3600-4000, so loading brake type dyno works best for these. Water brakes work good on vertical engines or up to 12,000 rpm. Also, they can go either direction, so good for 2-cycles? Water brakes (5-200 hp) are usually behind a month or two in getting so let me know and I’ll get you a quote. You’ll need good water volume or a very large recirculating tank.

We do hydraulic dynos for the same type of engines, with governors. Again, email for price? Large water coolers may be required on larger engines.

What’s new for 2022?

New Nanotechnology treatment for the axle bearings

We are going to a new armor coating process for axle bearings. It treats .004 into the steel, both the inner race, outer race & the ball bearings. It does not need any oil or grease.

We got the bearings & did a back-to-back dyno test. Dyno pull was 28.38 seconds on a stock clone with .036 jet, header, blueprint springs using a 40 hp dyno flywheel. Peak horsepower was 11.50. We installed the Nano treated bearings & time dropped to 25.78 seconds & horsepower climbed to 11.90. That’s a 2.6 second decrease in time & we had up to .6 horsepower increase in some places. If I was building a new dyno or needed to replace old bearings, this is definitely what I’d install! I hope to get the graph on my website. To add Nano Technology to 1 ¾” standard bearings, add $83.33 per bearing. To add Nano Technology bearings to a new dyno with 1 ¼” bearings, it would be $83.33 per bearing.

Low vibration motor mount rails

These are motor mount rails that are mounted in rubber in the international (wide) pattern. These may require replacement after several years as they may be affected by carb cleaner, brake clean, etc. These are meant to help 2 or 4-cycle engines with float type carbs. On some dynos you may have room for both types of rails.

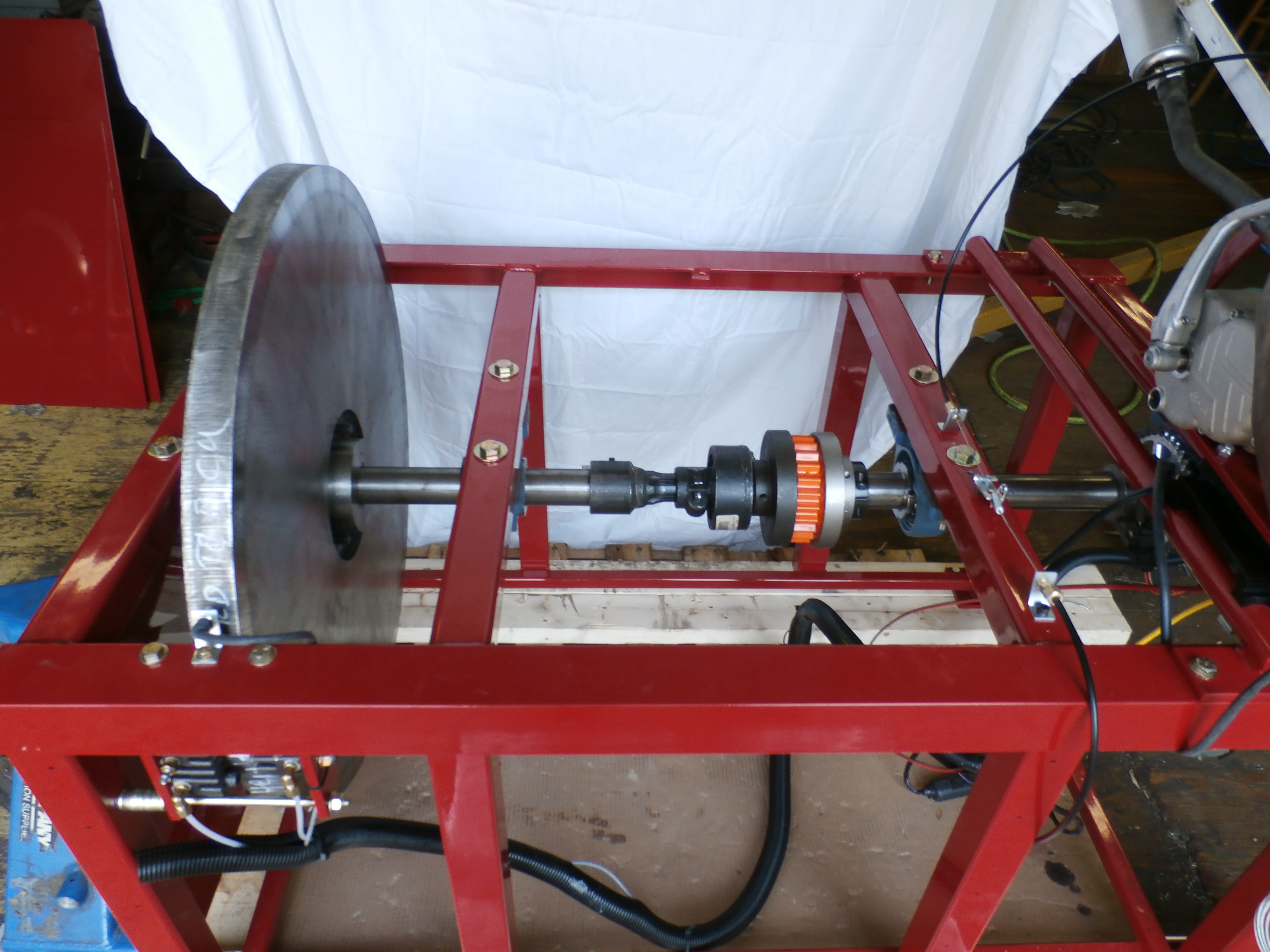

Kit Dynos

We are trying kits dynos again. I tried this years ago and I wasn’t happy with how things went, so I stopped it. Since steel prices and other parts have gone up in price quite a bit, I’m trying it again. We’re starting with the basics, 30 hp flywheel with 1 ¼” axle, basic data system, a refurbished computer updated & software installed and set up correctly. You’ll receive about 20-30 pictures with comments on pics to help you assemble it correctly. I’m hoping to write complete instructions this winter when I’m stranded at the house during a blizzard. You’ll need at least a 175-amp mig welder with .030” wire. Weld for strength not beauty. Here’s a list of tools you’ll need, wood door shims, 36” level, 48” drywall square, 8 welding c clamps (11r), 60” pipe clamp, 3/16” drill bits, 25/64” drill bits, 9/16” drill bits. I am sending you a complete estimate of everything I think you should have, and you tell me what you don’t want. I found a place with much cheaper freight costs too but tried it three times & it was a nightmare! I’m going to try them again just to get you cheaper freight and see if they can make it work a lot better than the last 3 times. If they work, it will cut freight costs by 30-40 percent.

Axles & Shafts

As of 09/01/20, we no longer use stress-proof steel. We’ve just had too many pieces undersized and out of round. And of course, caused problems. We use only turned, ground & polished 1 ¼”, 1 ¾”, 50mm, 2”(?) & 2 ¾”. Most of time its .001 undersize, but sometimes its right on the money and have to polish it on a crank grinder. We’d like to quit using 1 ¼”, but there’s so many people wanting a low-cost dyno, so we keep doing those.

DYNO TABLES

We know from experience that 2-cycles above 40 hp need to have heavy duty tables. The high frequency vibration somehow breaks the steel and/or welds. On 4-cycles you can go to 50 hp before going to heavy duty tables. This means ½” thick upper frame rails and ½” thick lower leg/frame supports. And if you choose flywheels with medium duty or heavy-duty or larger size bearings, you’ll need 3” wide cross members with ¼” wall rectangle tubing.

New Powder Coater

We’ve gone to a small powder coater that can do just about any color: polished aluminum, green, yellow, orange, satan black, red, blue, gray, white, hot pink, etc. The only problem is he’s 140 miles away to take it there & get it back, so the price isn’t going down.

Motor Mount Rails

Make sure you want 28mm/1 ⅛” motor mount rails if you’re a 2-cycle racer. A lot of times now, we’re installing 1 ¼” rails (about 97% of the time) and 1 ⅛” (28mm) on the same dyno. So, they can do their smaller engines on the 28mm set of rails & the high hp engines on 1 ¼” rails. Always on international rails (3 ⅝” center to center or 92mm c to c. Just checked out a Orthandal 2-cycle mount, it has 30mm & 32mm holes in the bottom of mount, so you can use 1 ¼” (32mm) with no problem.

Lower Dyno Frame Supports

For the last year or so we have been building all dyno tables so you can get under it from any side with a pallet jack. It allows you to move it about anywhere. Most pallet jacks are twenty-seven inches o.d. to o.d. of the lift arms. You may have to remove the dual pivot feet from the bottom of the legs because the bolts interfere. If you order casters or air bags, we will try & still put supports so the dyno can be moved with a pallet jack.

Freight Cost of New Dynos

Freight has been going up & I keep getting stuck eating a portion of the cost of freight. If my shipper looks up your address & it shows a house, then you will have to pay residential shipping. Also, make sure the trucker can get into your place of business. Lately, I’ve had a few truckers that would not deliver to a certain address because they can’t get into your driveway. I’m going to charge everyone with residential delivery with a lift gate unless you do have a business address & a way to unload from the truck (lift truck, Forklift, skid loader or tractor with forks, loading dock, etc.) If they can get it on the ground, you should be able to drag it where you need it with a pallet jack.

Large Flywheels, Low HP Engines

Lately we have been selling a lot of 40hp flywheels (9 in a row) and figuring out a way to still test smaller engines on the same dyno. If you don’t want to pay for two flywheels and everything that goes with them, we have a few options, #1 (a 110-tooth OR 120 tooth #219 sprocket, divide by 13 tooth #219 sprocket= 8.46 ratio), or #2 (an adjustable jackshaft with belt drive or chain drive (#35 or #219, etc.). We can do #35 chain jackshaft for about $950.00 or with low engagement 3 disc clutch, about $1300.00. This might also work for Quarter Midgets. Ratios would be for example 14.6 to 1, 21.49 to one & 29.12 to one.

It’s still a lot cheaper than 2 flywheels and everything that goes with it? I hate chains, belt drive is by far the best way to go, but it gets pricey! We will do chain gear reduction if you want it. We have #219 sprockets in 110 tooth & 120 tooth #219 sprockets.

Axles & Dyno Frames

Some basic guides on axles. 30 hp or smaller, we can use 1 ¼” axle’s as long as total length is under 24” long, 1 ¾” can be used on 20hp up to about 40 hp(4-cycle). 40hp & up, we need to use 50mm or 2” up to about 60-75 hp. Above that, I’d recommend (undetermined size as of now.). FRAMES- The standard dyno table can be used up to 40 hp on 2-cycles, maybe 50 hp on 4-cycles. After that (2-cycles), 40 hp & on up, we will have to use ½” upper frame rails & ½” thick middle supports and ¼” thick 2”x3” crossmembers. Especially 2-cycle engines. Their high frequency vibration tends to crack dyno frames, & welds above 40 hp.

Quarter Midgets

There are 3 different ways to build quarter midget dynos. One using a clutch (the cheapest way, a little crude but it works!) and 2nd using electric start with belt drive. Both measure horsepower and parasitic drag through the gearbox. So, by far the best. The 3rd way works well, but the cost is very high, so I’ve only done this once. It involves using an EDM (a type of laser to cut an exact gear) to make the sun gear into a drive shaft. We build them the first two ways.

STEEL & FLYWHEEL PRICES-LATE 2021-2022

In 2021, steel prices went up to the highest price ever recorded. We raised our prices at the same mark-up percentage we used for the last 21 years. Some of the steel I bought has quadrupled in price since the last time I purchased it. Flywheel prices have done the same, gone up a bunch! The vendor I’m using has the lowest prices of anyone I’ve found. Two other vendors I checked were 25% higher than my current source for flywheels. So, I’ll keep using my current source. He treats me well and does his best to get them to me quickly.

Current Flywheel Prices.

This is only the price of the flywheels. Normally 28” diameter with 6 ¾” i.d., Blanchard ground on both sides. Some flywheels can have several different axles, all turned, ground & polished with no keyways where the bearings run. Sizes= 1.25”, 1.75”, 50mm, 2” & 2 ¾”-not sure we’ll use this size. Industrial users use 2 11/16” or 2 9/16”, etc.

New One Piece 3.75” x 20.5”-to replace early flywheels in dual flywheel dyno-$1316.75.

30hp-$1379.78 -#3 seller

35hp-$1601.43 -#2 seller

40hp-$1623.67 -#1 seller by far

50hp-$1970.38

65hp-$2779.45

85hp-$3399.63

120hp-$5098.38 or

120hp=4”x31”-$5098.38

DIESEL STARTING SYSTEMS

We’re looking into bigger & faster cranking starter systems for dynos. These would be for bigger cu.in. diesel engines. Hope to try some soon. Also looking to try GM 153 tooth ring gears with big block starters. We may have a problem with starter mounts hitting center bearings, so may have to use 1 ¾” axles. We use Pontiac, Buick, Olds starters on axles above the frame. There are super starters for GM engines if you need one, but of course they are pricey ($350.00-$599.99).

DYNOS & PRICING

Almost any dyno can be sold as a P.A.K. or kit dyno. Let me know and I can give you a price.

Send me an e-mail with your zip code & tell me which dyno you’re interested in & I’ll send you an exact estimate.

- $7203.85-(#7640-06) New design. Dyno, 30hp flywheel, 1 ¼” large series bearings, New basic data system (measure hp., tq & acceleration), “Pro” software (overlay up to 6 graphs or reports), S.A.E. weather correction, refurbished intel I3 computer (1 year warranty). Optional, with new hard drive, add $60.00. 8 outlet surge protector & new 24” monitor. Optional: Dual temperature readings & (2) sensors (head, exhaust, water, air, etc.)=add $387.00 If you add air/fuel ratio ($599.99). You will need dual temp & you will lose one channel of temp reading on the basic data system to run air/fuel ratio. Go up to “pro” data system recommended. Comes with a new super duty clutch with correct springs & driver. No crating charge, dyno will be bolted to pallet & shrink wrapped only. Dyno is powder coated, but P.A.K. & KIT are not. I weld the dyno in the fixture and do all the work to complete flywheel/axle assembly. It is computer balanced to under 3 grams at 500 rpms. I also install the brake bracket (very critical, it’s installed correctly!) I weld all other parts, but you do all assembly work, mostly all the small parts. The computer will be updated, Windows 11 may be installed. Windows defender turned on, data system software installed & set-up & unlocked in your name, then we’ll do some basic tests to make sure it all works. The computer is ready to use when you get it.

2022 QUARTER MIDGET CLUTCH ADD-ON

This is a complete #35 & #219 clutch add on kit to add a clutch with a jackshaft conversion kit to add quarter midget engine testing to any clutch type or electric inertia dyno. Price is $1310.98 3-disc clutch or belt drive is optional.

(NEW) P.A.K. DYNO ($6114.46-(#7640-07)-Same dyno as above. I weld dyno table frame in jig, do assembly work & welding on flywheel together & get it computer balanced & install it. Make and install brake bracket and make sure it is bolted to leg horizontally. Then you do all the small finish work. Dyno is not powder coated and it is bolted to pallet & shrink wrapped, again to save you money.

(NEW) KIT DYNO ($5491.93-(#7640-57)-Same dyno as number one above but it comes with all the steel & parts banded on a pallet. Will include a complete ready to install axle/flywheel. Computer is updated, software installed & set-up & ready to use when you get it. You will be sent a complete picture assembly package & instruction. (As of 12/21/21 we do not have this done. Will be done on next dyno sold!)

- ($6699.99) #7483-Very common dyno if you have your own computer system & low rpm engagement clutch & motor mount. Dyno has 35 hp flywheel (add $40.00 for 40 hp flywheel), 1 ¾” axle & bearings, mini data system with S.A.E weather correction, gives you torque, horsepower & acceleration. You should also get eight outlet surge protector. It is powder coated in any color. I will need a zip code for the freight estimate. Don’t want powder coat or protective crating, Deduct -$400.00. Can add electric start & belt drive for optional price.

#2-($7199.99)-85(#7358) or $6799.99, see at bottom of section #2. -New design dyno (allows you to change belts or chain without dropping the axle). Has a 30hp flywheel on a short axle, to eliminate flywheel wobble. Fully assembled dyno that is powder coated & ready to use when you get it. Includes 24” monitor, refurbished computer with ssd hard drive is optional, 1 ¼” large series bearings, basic data system with S.A.E. weather correction, & “Pro” software, etc. PERFECT DYNO to add electric start & belt drive. NOTE: if you don’t want powder coat & crating for shipping protection, deduct $400.00. Your cost is then **($7599.99)****

#3 ($7710.37) (#7185) New design (change chain or belt without dropping axle!) with 35 hp flywheel, 1 ¾” turned, ground & polished axle with standard duty bearings, mini “Pro” data system, super duty titan clutch with correct springs & driver, small parts kit, crating charge. This will be a much smaller footprint dyno than standard dyno size. Can add electric start & belt drive.

#4 ($8146.57) (#7359)-BELT DRIVE CLUTCH DYNO-**Take out vibration & dyno is more accurate, better repeatability I’ve been told!** Same dyno as #3 except with 3-disc belt drive clutch, (2) belts & correct lower drive sprocket with qd inner hub. Belts last much longer than chain, and don’t seize or gall up like chain. Sometimes, chain can show up to 3/10ths of hp loss.

#5 ($7421.26) (#7187) The following is a P.A.K. dyno. Dyno will not be powder coated and will have no protective crating for shipment. It will be shrink wrapped for shipping. I weld the main table in the fixture & then weld all other parts of the dyno. I also do all set-up centering & welding on the flywheel, then do all assembly of the flywheel. Get it computer balanced, then install it in the table, get it where it needs to be & then weld the brake bracket & install it correctly. Install an electric start system. Update computer, turn on windows defender, install software & get it unlocked in your name, test what we can. Install flywheel magnet. Dyno is not powder coated! You install all the small parts to finish the dyno. Optional-could install Quarter Midget jackshaft kit so you can dyno those engines? ********Price unknown at this time??????????

#6 ($9771.98) #7802-PERFECT CLONE DYNO-Lower cost electric start 30 hp direct drive with belt drive dyno. 1 ¾” axle & standard bearings. No slippage, so very accurate. Perfect dyno for engines up to 30hp, including quarter midgets. Comes standard with 30mm belt drive, which works for everything except Animals & engines with lightweight aluminum flywheels. We can install an optional magneto kill switch to help with kick back on startup & shut down. Comes with a refurbished computer. The optional ssd hard drive is $60.00 more. One year warranty. New 24” monitor. USB mini data system. Temp channels optional ($375.00) You can always try a 30mm belt & if you break the belt, we can update you to the 50mm belt driver and belts.

#8 ($9947.55) (#7187+#7489)-Above dyno with heavy duty new style one-way overrunning sprag clutch with torsion shock bushing. From 2001 to about 2009, this was the number #1 selling dyno. **NOTE: This dyno can be made with a diesel starting system (more torque & higher cranking rpm) & larger 50mm axles & bearings for higher hp engines. If adding a diesel starter, you can add up to 45 hp flywheel. ***might be able to do this dyno a cheaper way with 1 ⅜”-6 spline flywheel axle.***

#8 ($10141.67) #6731-40 hp flywheel, with 1 ¾” turned, ground & polished axle, diesel electric start(best), economy 30mm belt drive kit, mini USB data system, New high-tech computer with solid state hard drive (1 yr. warranty) if I can find one, new 24” monitor, 8 outlet surge protector, S.A.E. weather correction, “Pro” software, protective crating & powder coating of any common color. Options-(50mm belt drive pulley & belts is optional for Animals or engine with lightweight flywheels), (110 tooth #219 sprocket-$33.99) (jackshaft kit for lower hp engines is available) (“Pro” belt drive, 30% larger, is optional, 4-cycles) (new 17.3” laptop or desktop with 24”).

#9 ($11628.28) #6732-”Pro” engine builder dyno, update dyno to 50mm axle, bearings & all other parts. Has 40 hp flywheel with diesel electric start & “Pro” 144 tooth belt drive, new Lenovo or Acer 17.3” laptop or desktop with 24” monitor, “Pro” data system with 4 channels temp, S.A.E. weather correction. This data system is expandable to 24 channels. ***This would be a good dyno for air bags, which take out 87% of vibration according to their data.($669.99) ***Or air casters with brakes will take out a lot of vibration. ($499.99)**

#10 ($???)-This quote is for two 40 hp flywheels on 1 ¾” axles, “pro” data system, refurb computer, 24” monitor, no sprag clutch.- need to know what flywheel sizes, axles & horsepower?) Dual flywheel clutch dyno, chose 30 to 100 hp or larger flywheels and chose axles, 1 ¾”, 50mm, or 2”, 2 ¾” or larger? Most of these dynos will be custom quotes/estimates. These will be heavy duty tables, choice of data systems? Best is email what you want & I’ll do a custom quote. We will have to talk on the phone a few times.

#11(???) Were working on 500 hp & 1000 hp inertia dynos for the midget & world of outlaw customers. But I got so busy this last year that we didn’t finish the quotes.

INERTIADYNO.COM L.L.C.

STAN HEWITT

717 WEST ST.

BRISTOW, IA 50611-9706

E-MAIL=HEWITTDYNO@GMAIL.COM

PHONE 641-775-3395